Aug. 10, 2021

AHEAD to Support Decarbonization at Petroleum Refineries Through MCH Hydrogen Supply Chain from Brunei

Chiyoda Corporation, Mitsubishi Corporation, Mitsui & Co., Ltd. and Nippon Yusen Kabushiki Kaisha (hereinafter “the partners”) are pleased to announce that they have signed an agreement with ENEOS Corporation (ENEOS) to supply hydrogen produced in Brunei for use in the latter’s refinery decarbonization trials. The hydrogen, which will be delivered via a saturated hydrocarbon called methylcyclohexane (MCH), will be supplied by the Advanced Hydrogen Energy Chain Association for Technology Development (AHEAD), an organization that was jointly established by the partners in July 2017.

Hydrogen has considerable potential as a clean energy. It emits no CO2 and can be used in power generation, mobility, and many other industries to play a key role in future efforts to decarbonize. Unfortunately, there are two rather significant technical hurdles that need to be cleared before a hydrogen society can be realized. One is developing a stable, large-scale, and long-distance supply network that is capable of linking suppliers and consumers in different parts of the world. The other is securing reliable, long-term storage.

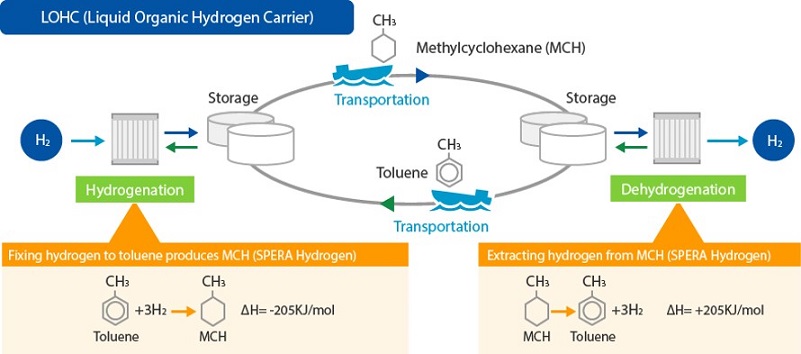

Composed of toluene and hydrogen, MCH is a liquid under normal temperature and atmospheric pressure, meaning that it can be both stored and transported using oil refineries, chemical tankers and other infrastructure that already exists to service the petroleum and petrochemicals industries. It is also an organic compound from which hydrogen can be extracted when necessary. AHEAD’s aim is to use MCH to help address these supply-and-storage challenges.

Backed by funding from NEDO1, AHEAD successfully completed trials of the world’s first international shipment of MCH and stable extraction of its hydrogen in 2020, when it delivered MCH produced in Brunei to Japan. For the ENEOS trials2, which are being funded by Japan’s consortium for resilient oil supply (CROS), AHEAD will ship the MCH using chemicals tankers and other carriers3.

At present, most of the industrial-use hydrogen in Japan is consumed during the desulfurization process at petroleum refineries4. This is so-called grey hydrogen, which is derived from fossil fuels in processes that emit CO2, however, replacing it with CO2-free hydrogen derived from MCH can help to reduce industrial CO2 emissions5. For that reason, AHEAD’s supply of MCH for the ENEOS trials promises to be a significant step towards using this organic compound more broadly as a means of transporting and storing hydrogen.

The partners are looking forward to future collaborations in a variety of industries that will help to one day realize hydrogen-powered societies.

Hydrogenation plant in Brunei

1. Japan’s New Energy and Industrial Technology Development Organization. From 2015 until 2020, NEDO conducted a global-supply-chain pilot project that used Chiyoda Corporation’s liquid organic hydrogen carrier (LOHC) technology to transport hydrogen from Brunei to Kawasaki City in Japan’s Kanagawa Prefecture. The technology uses MCH as a hydrogen carrier.

2. The objective of these trials is to make structural improvements to petrochemicals complexes that will strengthen them, raise their productivity, reduce their CO2 emissions and otherwise help to meet growing demands for their cleaner operation.

3. In 2020, AHEAD used 24-kiloliter ISO tank containers to ship the MCH in the NEDO-funded trials, however, in order to test the commercial viability of these shipments, it plans to use much larger, 10,000 DWT-class chemicals tankers for the ENEOS trials.

4. Source: "Report of 9th Working Group on CO2-Free Hydrogen" (Ministry of Economy, Trade and Industry’s Agency for Natural Resources and Energy)

5. Source: "Future Hydrogen Policy Issues and Direction of Measures: Interim Report" (Ministry of Economy, Trade and Industry’s Agency for Natural Resources and Energy)

The news on this website is as of the date announced and may change without notice.